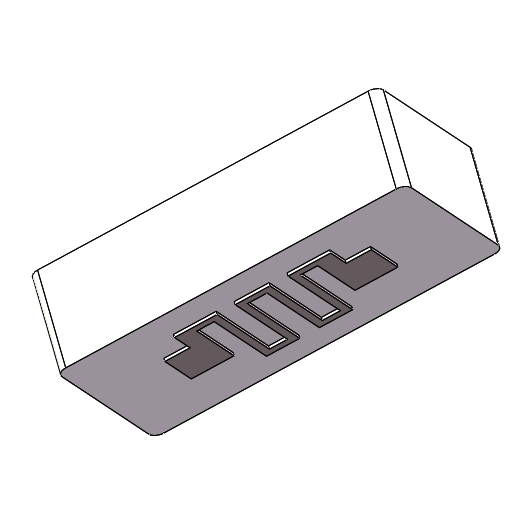

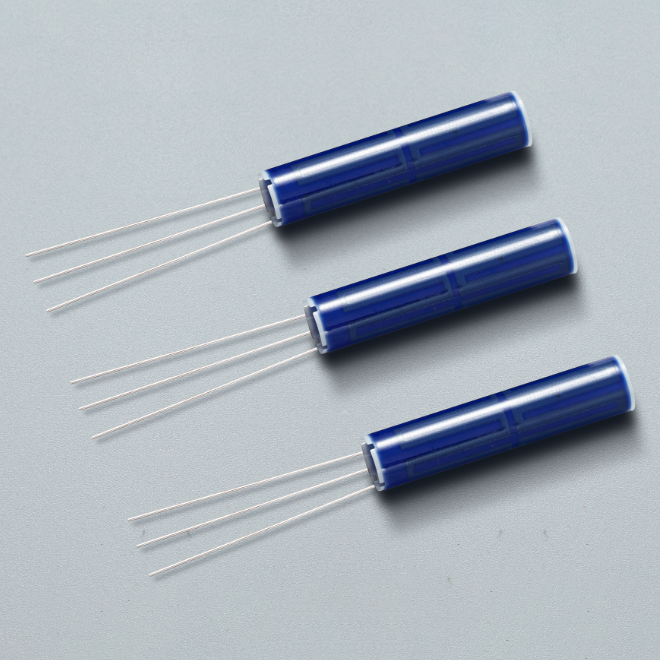

ZTA(Zirconia Toughened Alumina)

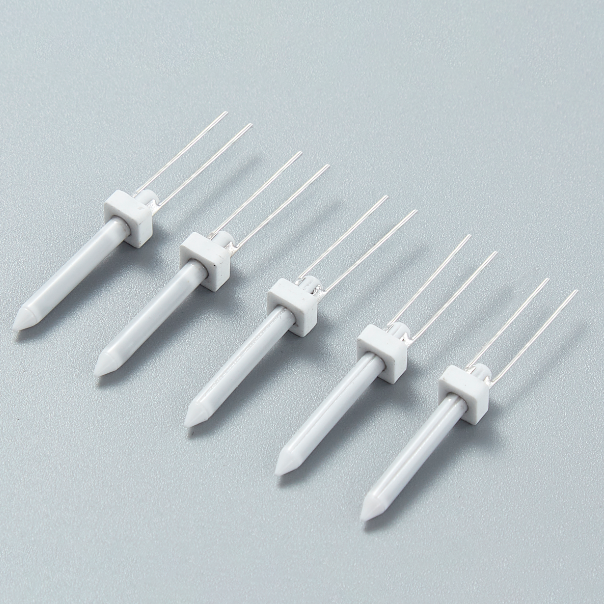

Introduction of Keycore III (ZTA)

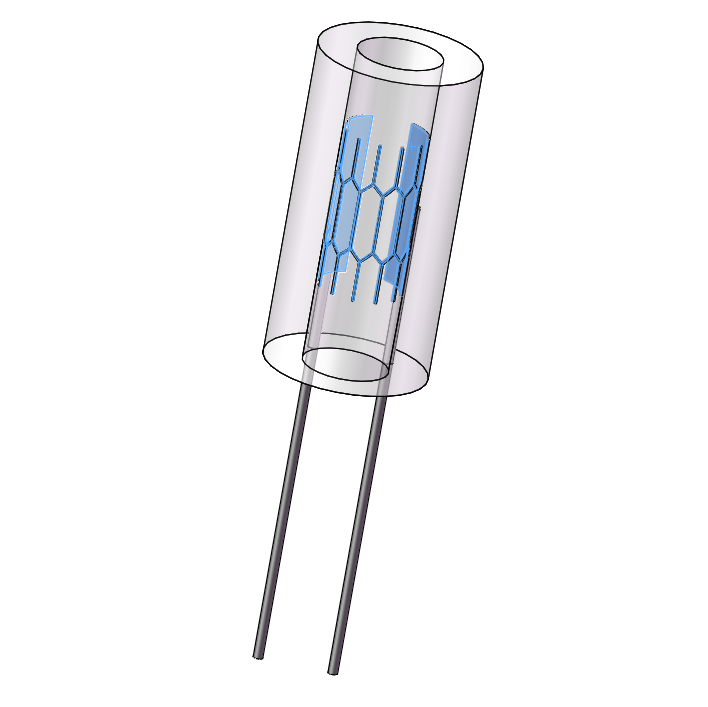

Internal hollow design

Zironia material

Electrode high temperature silver brazing

The bending strength can reach 15KG. It is three times larger tip zirconia heater (for IQOS) and 1.5 times larger than tip alumina heater.

Low energy consumption, 29% lower than Keycore I

Heating up fast, compared to alumina Keycore I, it fast 7.5 seconds up to 350 ℃, heating rapid increased by 1.7 times

Flange temperature is low, 30seconds in 350degrees, the flange temperature less than 100 ℃.

Diameter:2.15±0.1mm

Length:19±0.2mm

Heating Resistance:(0.6-1.5)±0.1Ω

Heating TCR:1500±200ppm/℃

Sensor Resistance:(11-14.5)±0.1Ω

Sensor TCR:3500±150ppm/℃

Lead Soldering Withstand Temperature:≤100℃

lead tensile force:(≥1kg)

Testing conditions: the working voltage shall make the surface temperature of the product reach 350 degrees, and then test the temperature of the flange after 30S of stability.

The flange temperature of Keycore II (HTCC ZCH) is lower when it works. The flange temperature after 30 seconds of maintaining a temperature of 350℃ at a working voltage of 3.7v is no more than 100℃, while that of Keycore I is around 210℃ under the same conditions.

Ceramic heaters are widely used in many fields due to their special properties and advantages, including but not limited to the following aspects:

Industrial heating: Ceramic heaters are often used in heating equipment in industrial production, such as plastic molding heating, rubber heating, glass heating, food heating and other fields.

Chemical industry: Due to the corrosion resistance of ceramic materials, ceramic heaters are often used for heating corrosive media in the chemical industry, such as the heating of acid and alkali solutions.

Medical equipment: Ceramic heaters are widely used in the field of medical equipment, such as heating and disinfection of medical equipment.

Household appliances: Ceramic heaters are also commonly used in household appliances, such as electric kettles, electric cups, electric blankets, etc

Automotive field: Ceramic heaters are also used in the automotive field, such as car seat heating, engine preheating, etc.

Other fields: Ceramic heaters are also used in aerospace, military, electronics, semiconductor and other fields to meet the heating needs in various special environments.

In general, ceramic heaters are widely used in industrial production, chemical industry, medical treatment, household appliances, automobiles and other fields, and their special properties make them ideal for many specific heating needs.

These elements are often used in environments where high temperatures are required, and where other materials might not be suitable due to their lower heat resistance. The use of ceramic heating elements has become increasingly popular in various industries due to their reliability and performance.