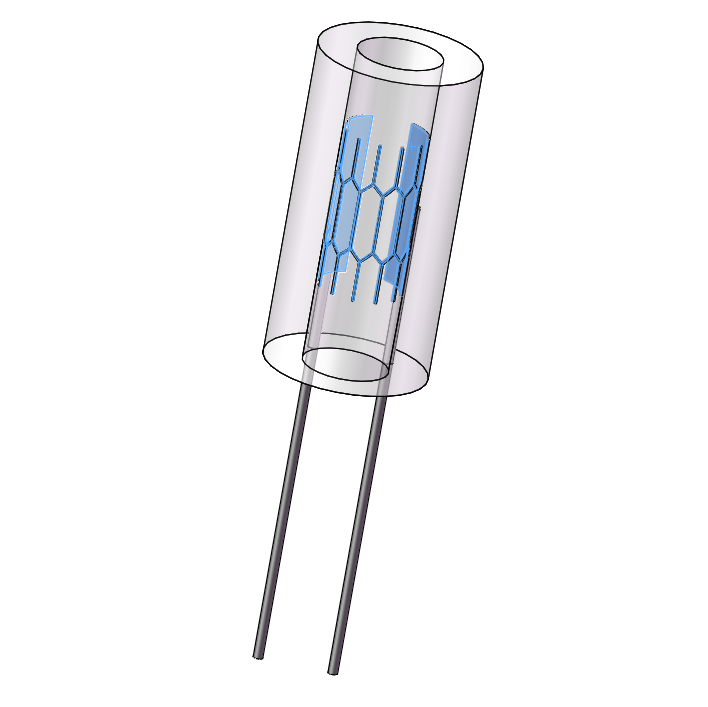

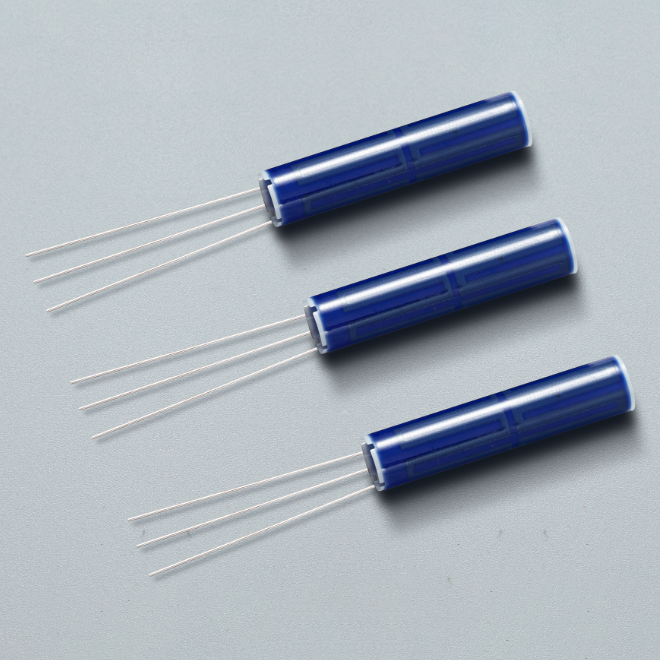

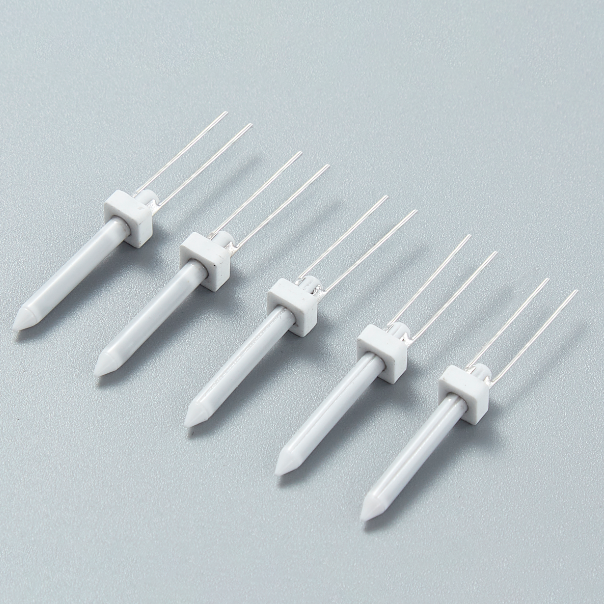

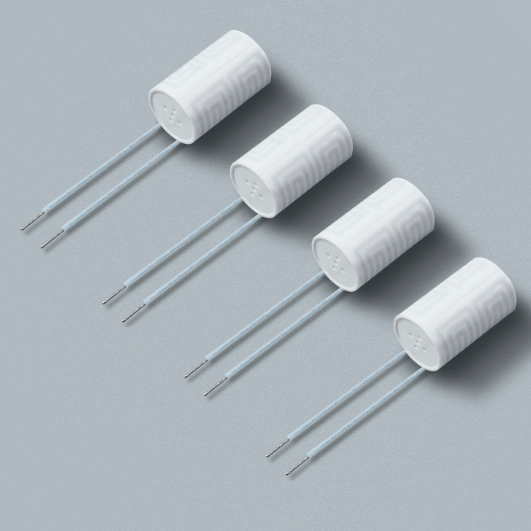

Zirconia Ceramic Heater Rod

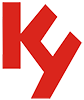

Introduction of Keycore Ⅱ (LTCC) of high temperature co-fired zirconia heating element

Fast temperature rise

Internal hollow design

Zironia material

Electrode high temperature silver brazing

The bending strength reach 15KG. It is three times larger plate zirconia heate and 1.5 times larger than tip alumina heater.

Low energy consumption, 29% lower than Keycore I

Heating up fast, compared to alumina Keycore I, it fast 7.5 seconds up to 350 ℃, heating rapid increased by 1.7 times

Flange temperature is low, 30seconds in 350degrees, the flange temperature less than 100 ℃.

Diameter:2.15±0.1mm

Length:19±0.2mm

Heating Resistance:(0.6-1.5)±0.1Ω

Heating TCR:1500±200ppm/℃

Sensor Resistance:(11-14.5)±0.1Ω

Sensor TCR:3500±150ppm/℃

Lead Soldering Withstand Temperature:≤100℃

lead tensile force:(≥1kg)

Testing conditions: the working voltage shall make the surface temperature of the product reach 350 degrees, and then test the temperature of the flange after 30S of stability.

The flange temperature of Keycore II (HTCC ZCH) is lower when it works. The flange temperature after 30 seconds of maintaining a temperature of 350℃ at a working voltage of 3.7v is no more than 100℃, while that of Keycore I is around 210℃ under the same conditions.

maintain stable performance in high temperature environments, so they are suitable for high temperature heating occasions.

Corrosion resistance: Ceramic materials have strong corrosion resistance, can work in some corrosive media, and are suitable for heating needs in special environments.

Insulation performance: Ceramic materials have good insulation properties, which can effectively prevent current leakage and improve the safety performance of the heater.

Uniform heating: Ceramic heaters can achieve a relatively uniform heating effect, avoiding local overheating or undercooling, and are suitable for occasions that require high heating uniformity.

Energy saving and environmental protection: Ceramic heaters usually have high energy efficiency and can convert electrical energy into heat energy with high efficiency, thereby reducing energy consumption and meeting the requirements of energy saving and environmental protection.

Long life: Because ceramic materials have good wear resistance and stability, ceramic heaters usually have a long service life.

In general, ceramic heaters have the characteristics of high temperature stability, corrosion resistance, insulation, uniform heating, energy saving and environmental protection, and long life, and are suitable for a variety of industrial and household heating occasions.