Ceramic Heater Tech

The main component of ceramic heater is Al2O3, which has advantages such as corrosion resistance, high temperature resistance, long service life, high efficiency and energy conservation, uniform temperature, good thermal conductivity, and fast thermal compensation speed. Moreover, the heater do not contain harmful substances such as lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers, and meet environmental requirements such as RoHS .

Alumina ceramic heater for water heater

A ceramic heating element is a type of heating component that is made from a ceramic material. It is commonly used in various heating applications, such as in space heaters, hair dryers, industrial furnaces, and even some cooking appliances.

Ceramic heating elements offer several advantages:

High-temperature capability: Ceramic materials can withstand high temperatures, making them suitable for applications requiring intense heat.

Rapid heating and cooling: Ceramic heating elements can heat up and cool down quickly, allowing for efficient temperature control.

Durability: Ceramic materials are known for their durability and resistance to corrosion, making ceramic heating elements long-lasting and reliable.

Thermal efficiency: Ceramic heating elements have good thermal conductivity, allowing for efficient heat transfer.

These elements are often used in environments where high temperatures are required, and where other materials might not be suitable due to their lower heat resistance. The use of ceramic heating elements has become increasingly popular in various industries due to their reliability and performance.

Ceramic Heater Tech

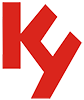

Tube Type

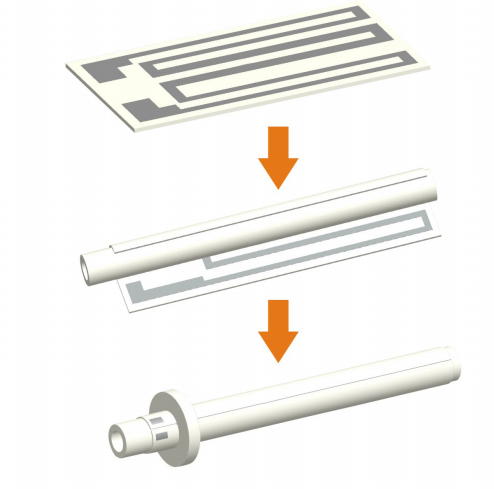

Plate Type

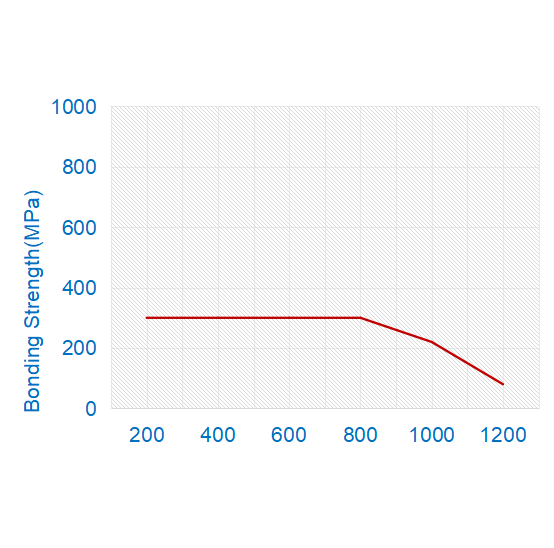

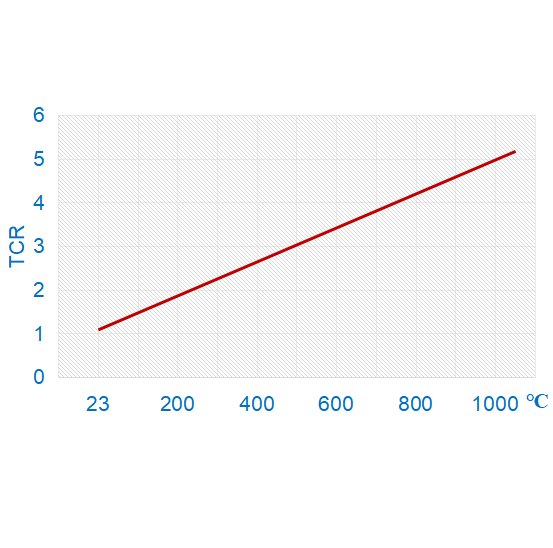

Alumina High Temp. Strength

Advantages of ceramic Heater

Fast heating rate

High efficiency

Small size and customize

Clean and environmental

Long service life

Oxidation and chemical resistance

Good insulation

Temperature sensing

Solutions

Heating

Ignite

Evaporate

Semiconductor

Medical

Specifications

Standard Specifications

・Max operating temperature: 1,000℃ MAX

・Specific heat (20℃): 0.78×103 J/(kg•K)

・Normal operation temperature: 800℃ MAX

・Linear expansion coefficient (40~800℃): 7.8×10-6/℃

・Thermal conductivity (20℃): 18 W/(m•k)

Standard dimensions

|

Structure |

Dimension(mm) |

Power |

||

|

Tube Ceramic Heater |

OD |

ID |

L |

2800-3000W |

|

Ø10-Ø14.5 |

Ø5.5-Ø9.5 |

80-106 |

||

|

Plate Ceramic Heater |

Length |

Width |

Thickness |

≤700w |

|

10-90 |

5-30 |

1.23-3.0 |

||