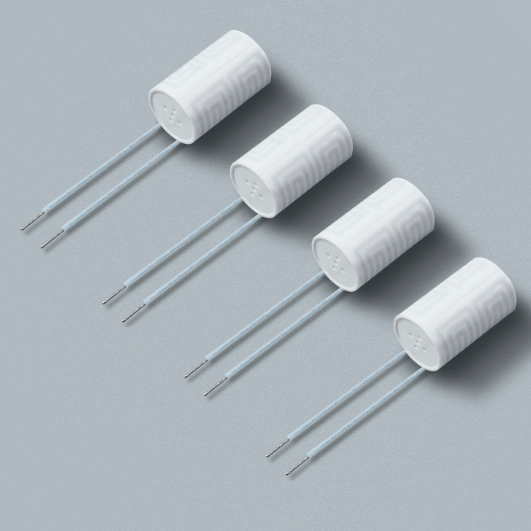

Ceramic Coil

Silicore Technical

Ideal atomization conditions are the equilibrium of power, heat and flow

1.Suitable atomization temp.:

Ideal atomization temperature for cigarette oil

2.Output power of the program board:

Power required to achieve desired atomization temperature

3.Structural design of airway and oilway:

Rationalization of airway design and rationalization of oilway design

Silicore technical is an atomization platform based on finding the balance between power, heat and flow.

Airway:

The airway affects oil leakage, condensate, etc. If the airway is not smooth, and the atomized smoke accumulates and stays on the airway, it will condense; the airway does not have a buffer ventilation structure. With the consumption of e-liquid, the air in the oil warehouse increases, forming a pressure difference, which must leak oil.

Oilway:

Poorly designed oil passages will lead to burnout and carbon buildup. If the oil passage is clogged with air bubbles, even the fastest atomizer core will be carbonized.

E-liquid Atomization Temperature:

To achieve the extreme taste, the ideal atomization temperature of the smoke oil is a necessity. Matching the thermodynamic properties and power of ceramic atomizer cores is key.

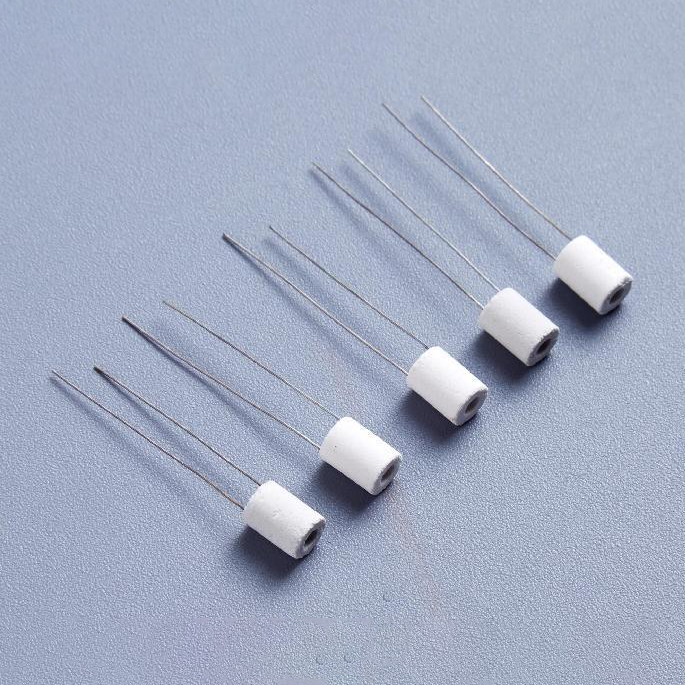

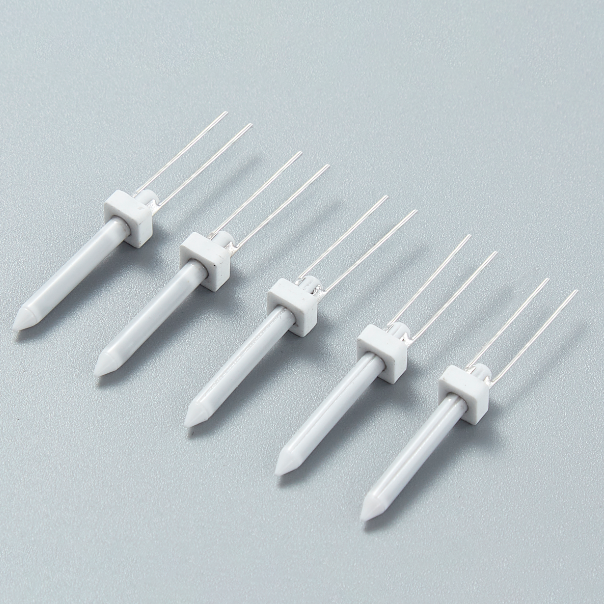

E-liquid type:

Disposable tobacco, moist and high-sweet e-liquid needs to choose a vertical hair ceramic coil,because the airway is short.

For bullet change and disposable delicate and fresh e-liquid, need to choose a flat ceramic coil.

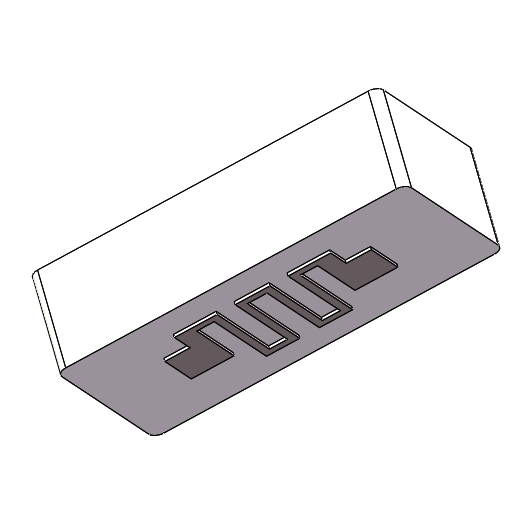

Power:

<7W choose thick film ceramic coil,which with strong burst, it only needs low power to reach the ideal atomization temperature;

>7.5W choose a SMD ceramic coil, which requires high power to achieve the desired atomization temperature.

Viscosity of tobacco liquid:

The viscosity of the e-liquid directly affects the atomization temperature. After determining the viscosity of the e-liquid, the ceramic coil is the best choice. The oil conduction speed is the oil conduction speed required to reach the ideal atomization temperature. Not too fast, not too slow.