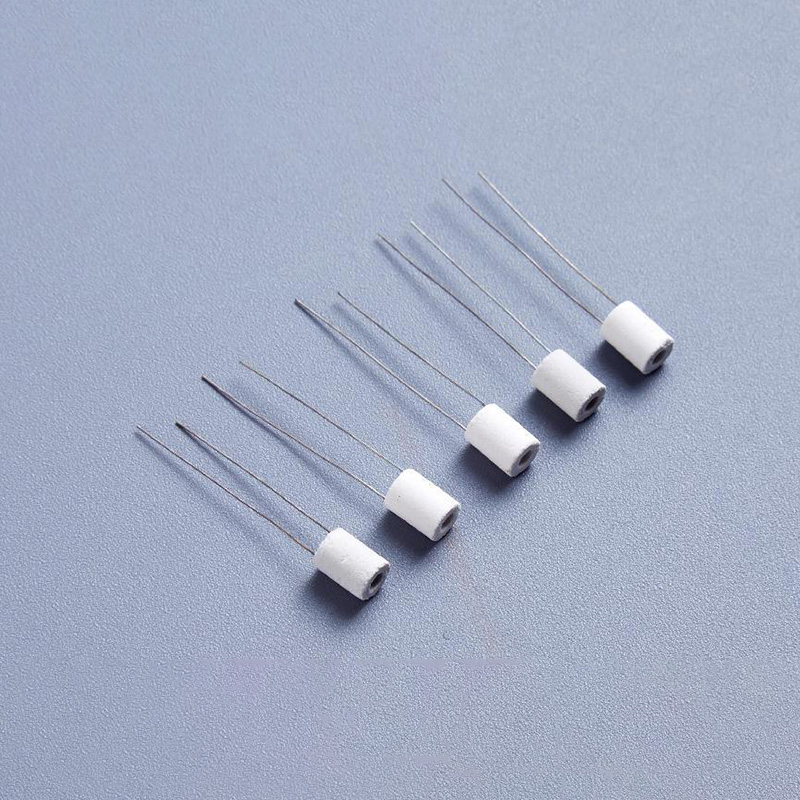

CBD ceramic core vape solution patent product for e-cigarette

Key Material Co., Ltd established in 2007, locating in Guangdong province, China. We are a high-tech enterprise specializing in researching, manufacture and sales of ceramic heater. We are a leading manufacturer of metal ceramic heaters in domestically, covering an area of 15,000㎡. The new production base covering 40,000㎡ is now processing, which can apply for production in 2019.

We work closely with research institutes and universities, the main partners are national laboratory of new materials, metal research institute, Chinese academy of sciences, national university of defense technology. We have strong technical development capability and techical team. We now have 55 patents, in the among of 11 invention patents, 7 international patents.

At present, the qualities of our technology research and development has a leading position in China. Looking forward to the future, we will make unremitting efforts to seek more efficient and thoughtful way to meet customer requirements, in the field of ceramic heating element, we expect to become the world leader.

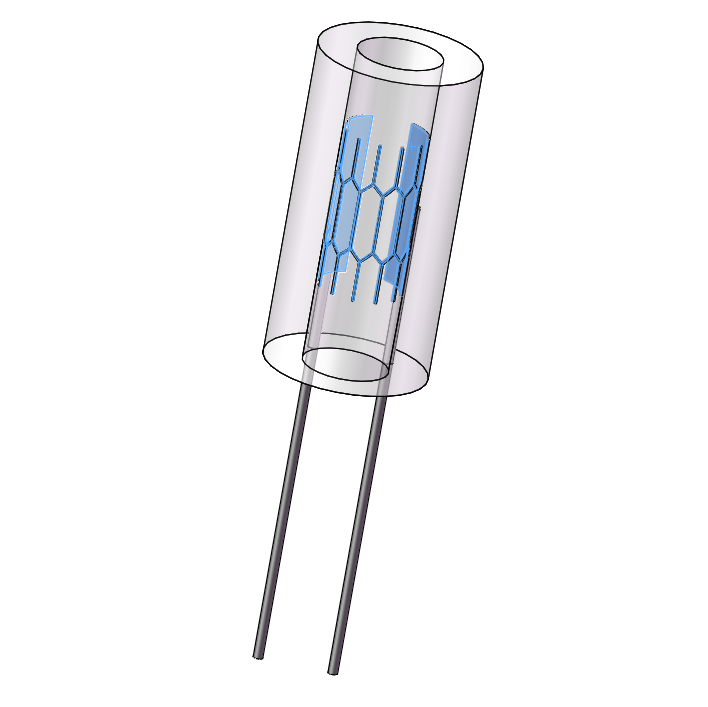

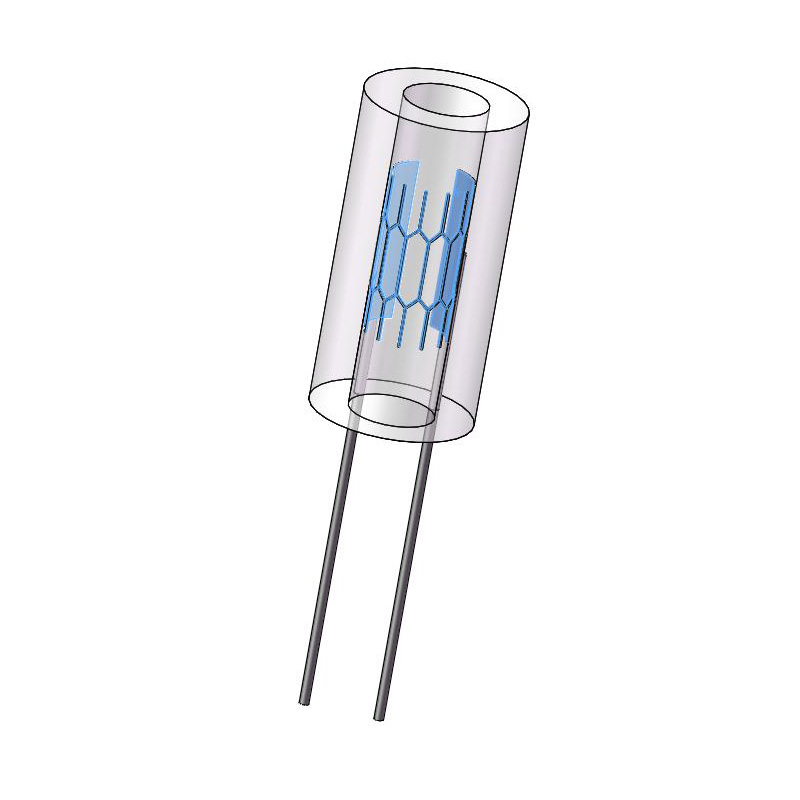

Silicore technical is an atomization platform based on finding the balance between power, heat and flow.

Airway

The airway affects oil leakage, condensate, etc. If the airway is not smooth, and the atomized smoke accumulates and stays on the airway, it will condense; the airway does not have a buffer ventilation structure. With the consumption of e-liquid, the air in the oil warehouse increases, forming a pressure difference, which must leak oil.

F-liquid Atomization Temperature

To achieve the extreme taste, the ideal atomization temperature of the smoke oil is a necessity. Matching the thermodynamic properties and power of ceramic atomizer cores is key.

E-liquid type

Disposable tobacco, moist and high-sweet e-liquid needs to choose a vertical hair ceramic coil,because the airway is short.

For bullet change and disposable delicate and fresh e-liquid, need to choose a flat ceramic coil.

Oilway

Poorly designed oil passages will lead to burnout and carbon buildup. If the oil passage is clogged with air bubbles, even the fastest atomizer core will be carbonized.

Power

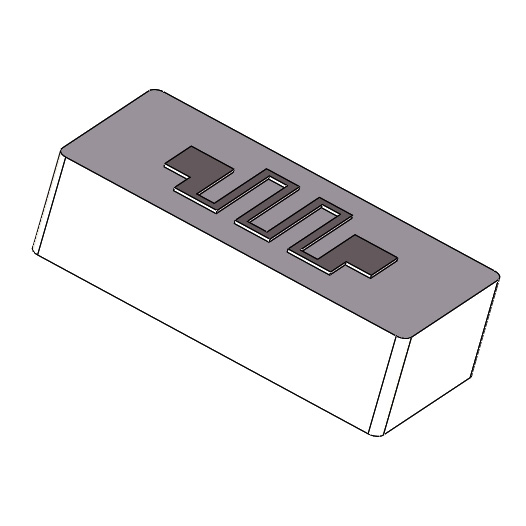

<7W choose thick film ceramic coil,which with strong burst, it only needs low power to reach the ideal atomization temperature;

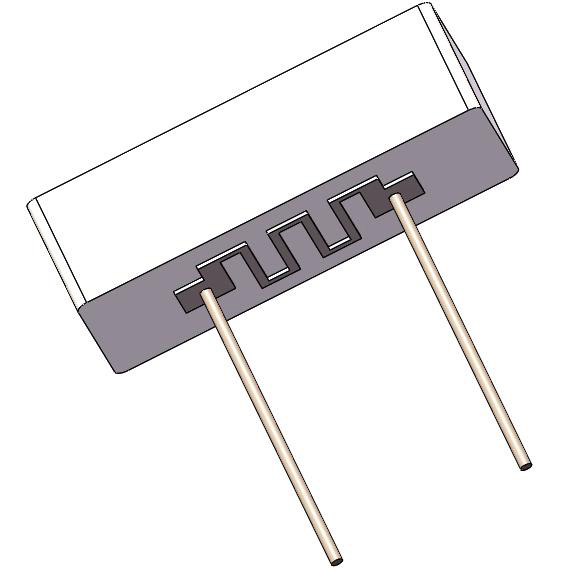

>7.5W choose a SMD ceramic coil, which requires high power to achieve the desired atomization temperature.

Viscosity of tobacco oil

The viscosity of the e-liquid directly affects the atomization temperature. After determining the viscosity of the e-liquid, the ceramic coil is the best choice. The oil conduction speed is the oil conduction speed required to reach the ideal atomization temperature. Not too fast, not too slow