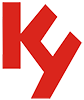

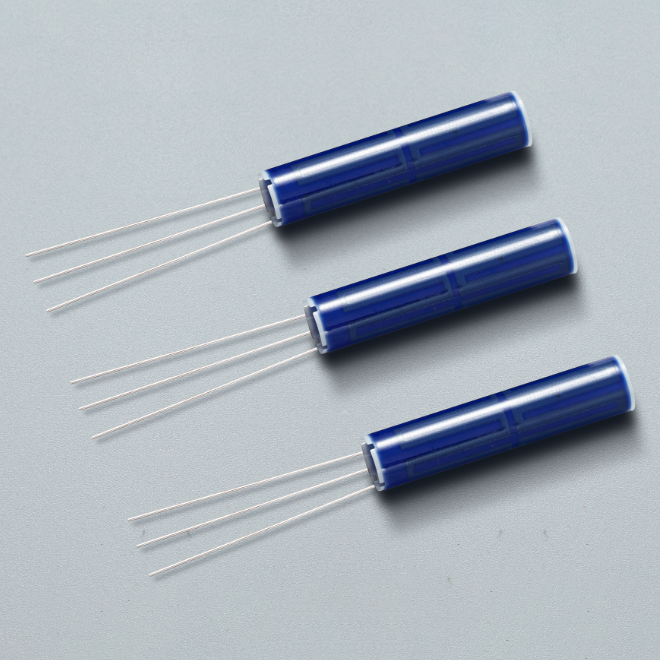

Alumina Ceramic Heater Rod for HNB

High-temperature capability: Ceramic materials can withstand high temperatures, making them suitable for applications requiring intense heat.

Rapid heating and cooling: Ceramic heating elements can heat up and cool down quickly, allowing for efficient temperature control.

Durability: Ceramic materials are known for their durability and resistance to corrosion, making ceramic heating elements long-lasting and reliable.

Thermal efficiency: Ceramic heating elements have good thermal conductivity, allowing for efficient heat transfer.

These elements are often used in environments where high temperatures are required, and where other materials might not be suitable due to their lower heat resistance. The use of ceramic heating elements has become increasingly popular in various industries due to their reliability and performance.

Performance:

Rod-shaped structure, high intensity, not easy to broken.

High temperature co-firing ceramic heating element, good compactness, heat line completely wrapped in ceramics.

Long-term use of high reliability.

Heating Rapidly, good uniformity.1000 ℃ silver brazing technology on solder joints, solder joint stability, resistant to 350 ℃ high temperature for a long time.

Resistance:

Heating Resistance: 0.6-0.9Ω, TCR 1500±200ppm/℃,

Rapidly heating, low energy consumes.

Sensor Resistance: 11-14.5Ω,TCR 3800±200ppm/℃.

Structure:

Size φ2.15*19mm, head shape is sharp, paste

coating surface.small diameter, smooth surface makes tobacco easy.flange itself makes it is easy for assembly.

Lead Soldering Withstand Temperature:≤100℃

lead tensile force:(≥1kg)

Testing conditions: the working voltage shall make the surface temperature of the product reach 350 degrees, and then test the temperature of the flange after 30S of stability.

The flange temperature of Keycore II (HTCC ZCH) is lower when it works. The flange temperature after 30 seconds of maintaining a temperature of 350℃ at a working voltage of 3.7v is no more than 100℃, while that of Keycore I is around 210℃ under the same conditions.